About Us

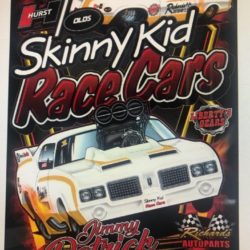

Skinny Kid Race Cars attention to detail is what makes them stand out from the rest. They are hands on with racers and they produce Champions!! They have built some of the most exciting cars to come on the drag racing scene in the past few years. They can build a car for whatever series you run, anything from a chassis to a complete turnkey car.

It was May 1999 at the second running of the World Ford Challenge when Don Walsh Jr. opened up his trailer and rolled out his brand-new Pro 5.0 ride. From that day forward the name Skinny Kid Race Cars (248/889-2542, www.skinnykidracecars.com) would be forever etched in the minds of racers, spectators and journalists. The new race car had magazine editors drooling and racers envious of what seemed like miles of chromoly tubing. Not many guys had heard of Keith Engling that day, but that would change by the end of the weekend. Walsh went on to grab the runner-up spot at WFC2, the biggest race of the season, and put his car into the coveted 7-second zone all during its first outing. Everyone stopped and took notice of those accomplishments and from there the phone started ringing from Mustang racers everywhere looking to hire Engling’s talents. Up until a few years ago Skinny Kid Race Cars was run out of a two car garage. But after he got popular in the local area and started doing more out-of-town work, a new facility was built to accommodate his business’s growth. The new building is huge, housing many chassis jigs and build plates. There is also an assortment of machines and enough material and inventory to build a fleet of Pro 5.0 cars.

The following year (2000) Engling had done a few more Pro 5.0 cars and then made his mark on the Super Street Outlaw field when a then-newly-constructed ’86 Mustang GT of the Testani Brothers scored a runner-up finish in their first outing at the NMRA’s All-Star Nationals in Columbus. Another customer to show off his Skinny Kid-built ride was Dan Millen, who ripped off 8.30s consistently in a handful of outings in 2000. “Everything on the car was flawless,” commented Millen about his legendary white coupe. He ended up at Engling’s shop before he moved into the new facility and was only known by local racers, “I went to Skinny Kid mainly after seeing Donny’s car, the fact that he was local, and some local guys used him.” People also got a good look at his work with Billy Glidden and the 2000 GT that he raced at NMRA’s St. Louis race. Those cars would only be a hint of what he could build for heads-up Mustang drag racing.

The 2001 racing season is where his recognition as being one of the premier chassis builders in Street Legal racing became a reality. His top two Pro 5.0 customers, Billy Glidden and Don Walsh Jr. scored the number one and number two spots in the NMRA Pro 5.0 Top 10 points battle with brand new Engling-designed and built tube-chassis Mustangs. “We went back [to Skinny Kid] mainly cause he did a beautiful job with the yellow car,” says Walsh. “Keith is very timely, when he says it’ll be done, it’ll be done.

That is something that is rare in the chassis business.” The new car was a success in its first season as Walsh became the first automatic-equipped Pro 5.0 car to run in the sixes and also became the first and only NMRA-legal 6-second blower car. Glidden became the first racer to win back-to-back Pro 5.0 titles at the World Ford Challenge. In addition to those outstanding achievements Glidden was the first and only nitrous powered Pro 5.0 car to run in the 6-second zone. According to those racers their accomplishments could not have been done without the hard work and talents of Engling.

Walsh put the coupe away in favor of this state-of-the-art Skinny Kid ride. Watch for this car to make a serious run for the Pro 5.0 crown in 2002.

Pro 5.0 racers were not the only ones who benefited from Engling’s work, as he has many customers who run well in Super Street Outlaw. Look no further than Dan Millen who busted out an unprecedented 7.89 at 177 mph in competition at an NMRA event in 2001. Or how about the Testanis, who are regarded as one of the most feared nitrous teams in the NMRA ranks these days? Those are just a few of the many race cars that Engling has in competition.

Do not be fooled into thinking that just the big name racers get the best Work. Each and every car is built by Engling himself and he puts the same hard work and engineering into each project. While we were visiting the shop he had numerous projects in various stages of completion, including a tube-chassis bracket car and several vehicles slated for Fastest Street Car racing. Of course he was also hard at work on Dan Millen’s new Mustang. In addition to the Pro 5.0 cars he built for Walsh and Glidden, look for Pande Talevsky and Nick Motta each to have a Skinny Kid Pro 5.0 car in 2002. We had just missed a new Hot Street car that will enter NMRA competition next season too, built for a new player to the wild world of heads-up Mustang drag racing. As exciting and busy as his shop is during this off-season, Engling took the time to sit down and answer a few questions for the Race Pages.

Race Pages: The cars of Don Walsh Jr. and Billy Glidden are top-notch race cars. The craftsmanship and engineering are rarely seen outside of the 'big shops' that do work for the NHRA/IHRA ranks. In addition to those trend-setting cars you are also the builder of the fastest Super Street Outlaw car (Dan Millen, 7.89) and many other top SSO cars. Have you ever thought about building Pro Stock or other 'Pro' cars?

Keith Engling: Yes. However that group is much harder to get involved with. At one point Chris Holbrook and I were talking about building an IHRA Pro Stock Cougar for him. Since that time he was able to obtain a sponsor for the next year, which will provide him with a car. So that didn’t work out quite the way we had planned.

Race Pages: How did you get started in building cars for drag racing? What is your history in the field of heads-up Mustang drag racing?

Keith Engling: In the early ’80s I really wanted to race but could not afford to have someone else build it for me, which inspired me to build my own. I started working on other people’s cars to help finance my racing. Five years ago I decided to quit my day job and try my luck at this full time. I found myself in business and I needed a name for the company. From the first day my wife and I met she had always called me the Skinny Kid. We thought it would be an unforgettable name, so we ran with it. I would have to say that my greatest thanks (outside of my wife Gail) would have to go to Donny Walsh Jr. His yellow coupe was the start of my involvement with the Ford racing world. The recognition and support from Donny himself opened up many doors such as Mike Testani, Dan Millen, Billy Glidden, Pande Talevsky, and many others. So on a personal note I would like to thank Donny for introducing me to the Ford racing world that I love so much.

Race Pages: The amount of horsepower seen in today's Pro 5.0 class has grown considerably over the last few years. How has that effected the way you build a race car for that class? What challenges are you faced with when building these cars?

Keith Engling: Turbo cars are challenging for a few reasons. First, these cars need to be full Pro Modified-style cars. These cars have so much torque you need a lot of chassis to keep them together. Second, which also applies to blower cars, is trying to design and package all the aftercooler plumbing, ice tanks, exhaust, etc. into the chassis and be able to keep it looking like wasn’t an afterthought.

Race Pages: You seem to be the crew chief and team consultant for Don Walsh Jr's Pro 5.0 car. What challenges are you faced with for the upcoming season?

Keith Engling: The biggest challenges I see for the upcoming season is NMRA’s lack of restriction on turbo cars. None of the turbo cars that ran this past season used their power efficiently. Believe me, teams like Grebeck, Rimmer, and Samuel are no dummies. They are all going to be going a lot quicker next season. I am not saying that we used our power as efficiently as we could have either, we have our own issues to sort out for the next season, but I don’t see us being able to catch the turbo cars in performance. Our team’s greatest asset would be Donny’s incredible reaction times and our consistency in getting down the track…and I hope I didn’t just jinx us here! As far as nitrous cars, trying to get that much power down on the marginal tracks we run on will be difficult and dangerous at 2,200 pounds. It’s even worse at 1,975 with an automatic, which is an impossible weight to get to anyway. These cars need to have a certain amount of static weight on the tires to keep them from getting very loose down track. Being light is only a benefit up to a certain point, and then it becomes dangerous.

Race Pages: Dan Millen certainly grabbed everyone's attention by running an amazing 7.89 at the NMRA Ford Motorsport Nationals. You are currently building a new car for him for the 2002 season. In your opinion is there an ET limit on how fast someone can go on the 28x10.5 tires?

Keith Engling: That is a really good question. I am in awe over what has been accomplished in this class. I can only take a small amount of credit. A huge portion of getting these cars down the track has to do with keeping the engine tune-up, gear ratios, and torque converter all working together, along with the suspension. I really feel that Dan Millen is about as good as they come at accomplishing this feat.

Race Pages: Just how do you go about building a Super Street Outlaw chassis capable of planting upwards of 1,700 horsepower?

Keith Engling: What I try to accomplish is to build a car as light as possible so I can have ballast to play with. Externally adjustable shocks and struts are a must. The other thing I feel that tends to be overlooked by racers is the front suspension. I get so many calls to the effect “What can I do to stop my car from wandering all over the track?” The first thing they suspect is the rear suspension. My advice is to address the front suspension before blaming all the trouble on the rear. Race cars must have adequate caster and zero bump steer.

Race Pages: Do you do any other kind of work for class specific cars like Renegade or Hot Street?

Keith Engling: Yes, I work on and/or built cars for Rob Galloway, Bob Jean, and Mike Tymensky, among others. I am also in the process of finishing a Hot Streeter for Ken Compton. I have also worked on Mike Wesley’s Real Streeter. [Ed. Note: Engling also works on Brand X cars. There was a 2000 Corvette with a tube-chassis setup for Nostalgia Pro Street that was completed before we got there].

Race Pages: Give us an idea of what it takes price-wise and time-wise to build a full-tilt Pro 5.0 and Super Street Outlaw car?

Keith Engling: Each car varies on power adders and components used. A Pro car takes four months, turbo and blower cars will take a little longer. Prices vary from $60,000 to $100,000-plus. Super Street Outlaw cars take three to four months for turnkey or six to eight weeks for a roller and range from $25,000 to $60,000.

Race Pages: What does the future hold for you and Skinny Kid Race Cars? Would you like to expand the shop and hire more people to build more cars, get into different types of racing, or anything else that you can see on the horizon? Would you like to race a car of your own?

Keith Engling: “We just built a 3,900 square-foot shop two years ago and have since hired two employees. I am quite content with the operation as it is today. I have no desire to become a mass production shop (ie Haas, Bickel, etc). I am directly involved with every single vehicle that comes through Skinny Kid Race Cars and that is exactly the way I always intend it to be. As far as different types of racing, I have no interest in cars that don’t know where the finish line is and drive for hours trying to find it. My next endevor will be to expand the mail order sales for the parts we now manufacture specifically for the mustangs. Racing a car of my own? I am in the process of building a new blown alcohol Pro Mod/Pro Street Outlaw car. This process has been going on for two years now, but I suspect I will eventually be completed and ready to race. But, right now as we speak, it is a very expensive shelving unit, as my customers come first.”